Small

CO2 footprint,

big career plans

ENABLER OF THE GREEN TRANSFORMATION

Our industry is in the midst of the greatest transformation in history – with the goal of complete climate neutrality. This involves nothing less than the fundamental renewal of our industrial foundations – and thus probably the greatest modernization and renewal since the Industrial Revolution.

As one of the world’s leading companies in technology and industry, we play a central role in this process. Together, we are moving forward to ensure a better future for ourselves and the generations to come.

The world needs more sustainability – we need you!

MAKE A DIFFERENCE – WITH US!

You’re not just looking for any job, but a real gamer-changer task? Then you’re in the right place with thyssenkrupp. Because that’s exactly what we do. Day by day!

We drive the green transformation in all areas. And on an industrial scale. So that we can make a difference.

Our motto: Be active. Join #GENERATIONTK!

Until

2030

Reduce our OWN emissions by 30 %

Until

2050

climate neutrality

OUR CLIMATE STRATEGY

Our mission: to drive the green transformation of an entire industry. We are not satisfied with anything less!

We have been optimizing the energy and climate efficiency of our production for many years. Together with our customers, we develop efficient solutions and innovative products to reduce greenhouse gases.

The success of our climate efforts is also regularly confirmed by independent bodies: For example, In 2023 thyssenkrupp has been included in the A-list of the renowned non-profit organization CDP (formerly Carbon Disclosure Project) for the eighth time in succession. This means we have once again been recognized as one of the world’s leading companies in climate protection.

We are now taking the next step in the further development of our climate strategy and setting ourselves the next ambitious targets: At thyssenkrupp we aim to be completely climate neutral by 2050 at the latest, in individual areas and countries significantly earlier.

This will be achieved through our Climate Action Program for Sustainable Solutions (CAPS).

This means:

- We optimize our own processes (#IMPLEMENT).

- We enable our customers to achieve their climate goals with our products and solutions (#ENABLE)

- We engage in socio-political dialog for a climate-neutral future (#ENGAGE).

This will be achieved through our Climate Action Program for Sustainable Solutions (CAPS).

This means:

- We optimize our own processes (#IMPLEMENT).

- We enable our customers to achieve their climate goals with our products and solutions (#ENABLE)

- We engage in socio-political dialog for a climate-neutral future (#ENGAGE).

This will be achieved through our Climate Action Program for Sustainable Solutions (CAPS).

This means:

- We optimize our own processes (#IMPLEMENT).

- We enable our customers to achieve their climate goals with our products and solutions (#ENABLE)

- We engage in socio-political dialog for a climate-neutral future (#ENGAGE).

“Climate protection and decarbonisation are key future and growth areas for thyssenkrupp. Our company has excellent expertise in building green value chains around the emerging global hydrogen industry and beyond. There are huge opportunities in all our businesses. We want to make the best possible use of these opportunities in the interests of climate protection and the further development of thyssenkrupp.”

Miguel Ángel López Borrego

CEO thyssenkrupp AG & thyssenkrupp Decarbon Technologies

DON´T DELAY,

DELIVER

WE ARE ALREADY DOING THIS TODAY - ARE YOU WITH US?

We are paving the way for the green transformation. We integrate climate protection and energy efficiency at all levels and set standards at all stages of the value chain: In production, across the entire supply chain, in our internal processes, all the way to implementation at our customers’ sites. With our pioneering solutions, we are shaping a resource-efficient future for ourselves and the next generations.

In doing so, we enthusiastically focus on particularly significant areas. Especially in our unit thyssenkrupp Decarbon Technologies, we are already pooling and developing sustainable solutions for tomorrow. And for this, we need you and your drive to make a difference!

SUSTAINABLE STEEL

At around 30%, conventional steel production accounts for the largest share of industrial greenhouse gas emissions in Germany. It’s time to take action. The good news is: we are already on it. With our solutions for green steel production, we will make a significant contribution to reducing climate-damaging emissions. The use of green hydrogen at thyssenkrupp Steel is the key step in making the steel industry more environmentally friendly: We are replacing the blast furnaces with a direct reduction technology. The result: No CO2, more water vapor. Hydrogen instead of coal is the goal. To achieve this, at the beginning of March thyssenkrupp Steel awarded a billion euro contract for a direct reduction plant to the SMS group. One of the world’s biggest industrial decarbonization projects with an order volume for SMS alone of over 1.8 billion euros.

It is a groundbreaking concept with a capacity of 2.5 million tons of direct-reduced iron. The plant is scheduled to start operations by the end of 2026. The annual CO2 savings amount to over 3.5 million tons. And therefore a win-win for us all. Do you want to revolutionize steel production with us? Then become part of #nextgenerationsteel!

At around 30%, conventional steel production accounts for the largest share of industrial greenhouse gas emissions in Germany. It’s time to take action. The good news is: we are already on it. With our solutions for green steel production, we will make a significant contribution to reducing climate-damaging emissions. The use of green hydrogen at thyssenkrupp Steel is the key step in making the steel industry more environmentally friendly: We are replacing the blast furnaces with a direct reduction technology. The result: No CO2, more water vapor. Hydrogen instead of coal is the goal. To achieve this, at the beginning of March thyssenkrupp Steel awarded a billion euro contract for a direct reduction plant to the SMS group. One of the world’s biggest industrial decarbonization projects with an order volume for SMS alone of over 1.8 billion euros.

It is a groundbreaking concept with a capacity of 2.5 million tons of direct-reduced iron. The plant is scheduled to start operations by the end of 2026. The annual CO2 savings amount to over 3.5 million tons. And therefore a win-win for us all. Do you want to revolutionize steel production with us? Then become part of #nextgenerationsteel!

At around 30%, conventional steel production accounts for the largest share of industrial greenhouse gas emissions in Germany. It’s time to take action. The good news is: we are already on it. With our solutions for climate-friendly steel production, we will make a significant contribution to reducing climate-damaging emissions. The use of green hydrogen at thyssenkrupp Steel is the key step in making the steel industry more environmentally friendly: We are replacing the blast furnaces with a direct reduction technology. The result: No CO2, more water vapor. Hydrogen instead of coal is the goal. To achieve this, at the beginning of March thyssenkrupp Steel awarded a billion euro contract for a direct reduction plant to the SMS group. One of the world’s biggest industrial decarbonization projects with an order volume for SMS alone of over 1.8 billion euros.

It is a groundbreaking concept with a capacity of 2.5 million tons of direct-reduced iron. The plant is scheduled to start operations by the end of 2026. The annual CO2 savings amount to over 3.5 million tons. And therefore a win-win for us all. Do you want to revolutionize steel production with us? Then become part of #nextgenerationsteel!

HYDROGEN

With our electrolysis business, thyssenkrupp nucera is already one of the few suppliers worldwide to offer technologies for the production of CO2-neutral green hydrogen on a gigawatt scale. After all, green hydrogen plays the decisive role in CO2 neutrality. After all, green hydrogen plays a crucial role in achieving CO2 neutrality, not only for the future-oriented direction of the steel industry but for the entire industry. With green hydrogen as a key component, industrial companies can make their production more sustainable and drastically reduce their CO2 emissions. Do you want to join us in creating an industry powered by clean energy?

With our electrolysis business, thyssenkrupp nucera is already one of the few suppliers worldwide to offer technologies for the production of CO2-neutral green hydrogen on a gigawatt scale. After all, green hydrogen plays the decisive role in CO2 neutrality. After all, green hydrogen plays a crucial role in achieving CO2 neutrality, not only for the future-oriented direction of the steel industry but for the entire industry. With green hydrogen as a key component, industrial companies can make their production more sustainable and drastically reduce their CO2 emissions. Do you want to join us in creating an industry powered by clean energy?

Green hydrogen plays the decisive role in CO2 neutrality. Not only for the future-oriented direction of the steel industry but in the entire industry. With green hydrogen as a key component, industrial companies can make their production more sustainable and drastically reduce their CO2 emissions. With our electrolysis business, thyssenkrupp nucera is already one of the few suppliers worldwide to offer technologies for the production of CO2-neutral green hydrogen on a gigawatt scale. In order to manufacture the necessary electrolysers or the fuel cells required for power generation in large-scale production cost-efficiently, thyssenkrupp Automation Engineering supplies the necessary production and test systems. Do you want to join us in creating an industry powered by clean energy?

AMMONIA

Everyone is talking about green hydrogen as the technology of the future. But who takes care of the transportation of H2? We do! By building innovative ammonia plants, we at thyssenkrupp Uhde not only make fertilizer more sustainable, but also enable an efficient, low-emission hydrogen transport worldwide. Are you ready to become a green pioneer and make a real impact?

Everyone is talking about green hydrogen as the technology of the future. But who takes care of the transportation of H2? We do! By building innovative ammonia plants, we at thyssenkrupp Uhde not only make fertilizer more sustainable, but also enable an efficient, low-emission hydrogen transport worldwide. Are you ready to become a green pioneer and make a real impact?

Everyone is talking about green hydrogen as the technology of the future. But who takes care of the transportation of H2? We do! By building innovative ammonia plants, we at thyssenkrupp Uhde not only make fertilizer more sustainable, but also enable an efficient, low-emission hydrogen transport worldwide. Are you ready to become a green pioneer and make a real impact?

GREEN METHANOL

Methanol is one of the most frequently produced organic chemicals in the world. Whether in the chemical, construction or plastics industry, it has become indispensable. However, the conventional production of methanol so far utilizes fossil resources such as natural gas. We at thyssenkrupp are changing that – with our uhde® Green Methanol technology from thyssenkrupp Uhde. By using green hydrogen and carbon dioxide, for example from biogas or other fermentation plants, we enable the production of green methanol. This reduces the amount of greenhouse gases emitted. Do you want to join us and help shaping a greener future?

Methanol is one of the most frequently produced organic chemicals in the world. Whether in the chemical, construction or plastics industry, it has become indispensable. However, the conventional production of methanol so far utilizes fossil resources such as natural gas. We at thyssenkrupp are changing that – with our uhde® Green Methanol technology from thyssenkrupp Uhde. By using green hydrogen and carbon dioxide, for example from biogas or other fermentation plants, we enable the production of green methanol. This reduces the amount of greenhouse gases emitted. Do you want to join us and help shaping a greener future?

Methanol is one of the most frequently produced organic chemicals in the world. Whether in the chemical, construction or plastics industry, it has become indispensable. However, the conventional production of methanol so far utilizes fossil resources such as natural gas. We at thyssenkrupp are changing that – with our uhde® Green Methanol technology from thyssenkrupp Uhde. By using green hydrogen and carbon dioxide, for example from biogas or other fermentation plants, we enable the production of green methanol. This reduces the amount of greenhouse gases emitted. Do you want to join us and help shaping a greener future?

E-MOBILITY

Electromobility is revolutionizing the way we get around. With our innovative automotive solutions we are helping e-mobility gain further momentum. At thyssenkrupp we have plenty in store for this: Lightweight solutions specially designed for electromobility and highly stable battery housings are just some of the pioneering systems and modules. In addition, at thyssenkrupp Automotive Technology we develop components for particularly efficient electric drives that are also used in e-vehicles. Will you join us and steer thyssenkrupp towards sustainability?

Electromobility is revolutionizing the way we get around. With our innovative automotive solutions we are helping e-mobility gain further momentum. At thyssenkrupp we have plenty in store for this: Lightweight solutions specially designed for electromobility and highly stable battery housings are just some of the pioneering systems and modules. In addition, at thyssenkrupp Automotive Technology we develop components for particularly efficient electric drives that are also used in e-vehicles. Will you join us and steer thyssenkrupp towards sustainability?

Electromobility is revolutionizing the way we get around. With our innovative automotive solutions we are helping e-mobility gain further momentum. At thyssenkrupp we have plenty in store for this: Lightweight solutions specially designed for electromobility and highly stable battery housings are just some of the pioneering systems and modules. In addition, at thyssenkrupp Automotive Technology we develop components for particularly efficient electric drives that are also used in e-vehicles. Will you join us and steer thyssenkrupp towards sustainability?

WIND ENERGY

We are well aware that fossil resources are becoming scarce, energy demand is increasing, and energy costs are rising. Worldwide. For these global challenges, we develop sustainable solutions. We are consistently working to drive environmentally friendly energy forward. For example, at thyssenkrupp rothe erde, we are pioneers in key components for wind turbines and world leaders in large slewing bearings. The company specializes in the production of large slewing bearings, roller bearings, and seamless rolled rings that are used in the international industry. We have mastered the important wind power sector. With us, you have the opportunity to be part of something big and make a significant impact. For a greener future, for this generation and the next. Are you in?

We are well aware that fossil resources are becoming scarce, energy demand is increasing, and energy costs are rising. Worldwide. For these global challenges, we develop sustainable solutions. We are consistently working to drive environmentally friendly energy forward. For example, at thyssenkrupp rothe erde, we are pioneers in key components for wind turbines and world leaders in large slewing bearings. The company specializes in the production of large slewing bearings, roller bearings, and seamless rolled rings that are used in the international industry. We have mastered the important wind power sector. With us, you have the opportunity to be part of something big and make a significant impact. For a greener future, for this generation and the next. Are you in?

We are well aware that fossil resources are becoming scarce, energy demand is increasing, and energy costs are rising. Worldwide. For these global challenges, we develop sustainable solutions. We are consistently working to drive environmentally friendly energy forward. For example, at thyssenkrupp rothe erde, we are pioneers in key components for wind turbines and world leaders in large slewing bearings. The company specializes in the production of large slewing bearings, roller bearings, and seamless rolled rings that are used in the international industry. We have mastered the important wind power sector. With us, you have the opportunity to be part of something big and make a significant impact. For a greener future, for this generation and the next. Are you in?

DIGITIZED PRODUCTION AND GREEN SUPPLY CHAINS

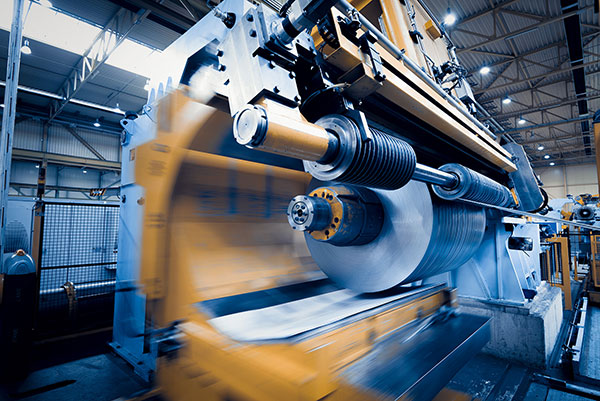

It’s time to act sustainably. And this also applies to logistics and production. Consistently optimized, both disciplines can contribute significantly to reducing CO2 emissions. By using advanced technologies such as the Internet of Things (IoT), artificial intelligence and automated processes, production processes can be digitalized and resource efficiency maximized. It’s all part of everyday life at thyssenkrupp Materials Services. Here we actively promote and successfully implement green supply chains and actively work to reduce the CO2 footprint of the entire industrial sector. With us, you can turn words into actions because we have a lot to offer when it comes to sustainability. Are you ready to deliver?

It’s time to act sustainably. And this also applies to logistics and production. Consistently optimized, both disciplines can contribute significantly to reducing CO2 emissions. By using advanced technologies such as the Internet of Things (IoT), artificial intelligence and automated processes, production processes can be digitalized and resource efficiency maximized. It’s all part of everyday life at thyssenkrupp Materials Services. Here we actively promote and successfully implement green supply chains and actively work to reduce the CO2 footprint of the entire industrial sector. With us, you can turn words into actions because we have a lot to offer when it comes to sustainability. Are you ready to deliver?

It’s time to act sustainably. And this also applies to logistics and production. Consistently optimized, both disciplines can contribute significantly to reducing CO2 emissions. By using advanced technologies such as the Internet of Things (IoT), artificial intelligence and automated processes, production processes can be digitalized and resource efficiency maximized. It’s all part of everyday life at thyssenkrupp Materials Services. Here we actively promote and successfully implement green supply chains and actively work to reduce the CO2 footprint of the entire industrial sector. With us, you can turn words into actions because we have a lot to offer when it comes to sustainability. Are you ready to deliver?

CO2-REDUCED CEMENT

A tough challenge: Approximately 7% of global CO2 emissions come from the cement industry. Every day, we strive to make this gray industry greener. At thyssenkrupp Polysius, we develop technologies and solutions for sustainable cement production, without losing sight of the profitability and productivity of the plants. Do you want to get involved and drive the green transformation together with us?

A tough challenge: Approximately 7% of global CO2 emissions come from the cement industry. Every day, we strive to make this gray industry greener. At thyssenkrupp Polysius, we develop technologies and solutions for sustainable cement production, without losing sight of the profitability and productivity of the plants. Do you want to get involved and drive the green transformation together with us?

A tough challenge: Approximately 7% of global CO2 emissions come from the cement industry. Every day, we strive to make this gray industry greener. At thyssenkrupp Polysius, we develop technologies and solutions for sustainable cement production, without losing sight of the profitability and productivity of the plants. Do you want to get involved and drive the green transformation together with us?

AMBITIOUS GOALS -

IMPRESSIVE FIGURES

Last fiscal year, we already reduced our CO2 emissions by 1.6 million metric tons! This is an important step toward our goal of climate neutrality by 2050 at the latest. With our innovative products and solutions, we also support our customers in achieving their climate goals.

In the past fiscal year we set ourselves the target of increasing energy efficiency at thyssenkrupp by 110 GWh. We actually more than doubled this target to around 255 GWh!

In the last fiscal year alone, we filed 1,500 new patent and utility model applications. This means that our patent portfolio currently comprises 17,370 patents and utility models – including numerous innovations in the area of sustainability.

Every year, we conduct at least 60 sustainability audits of suppliers. In this way, we actively support them in becoming more sustainable.

YOU WANT TO LEARN MORE?

Dive deeper into the topics of green transformation and climate protection at thyssenkrupp:

GET TO KNOW THE #GENERATIONTK

Future doesn’t happen, future is made. And every day. As #GENERATIONTK, we are making a difference and driving the green transformation. Learn more here.

Interview with hydrogen expert Dr. Christoph Noeres

Environmental protection and sustainability as a matter of the heart

On a climate mission. Dr. Marie Jaroni on the road to green steel

Najat Aya: part of the climate-neutral steel production team

The potential of green ammonia for our climate

Bright minds, innovative ideas and great drive. These are probably the most important attributes to achieve our climate goals. And this is what you can find a lot at thyssenkrupp. Here, you have the chance to get active and help shape the industry of tomorrow. Now it is up to you: Are you ready to be part of the green transformation? For a better future for us and of course the next generations?